Effective efficient engineering design to accelerate business strategy

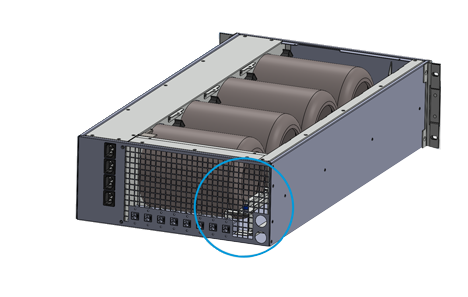

Racklive excels in providing Design-to-Order solutions tailored for the complexities of modern IT infrastructure. From intricate system configurations to specialized rack setups, our team collaborates with you every step of the way. Whether navigating power constraints, implementing high-density computing solutions, or requiring customized support brackets, our goal is to align tailor-made solutions with your business vision and infrastructure requirements, optimizing your IT environment with precision and expertise.